| ArcFM Desktop Overview > Designer > Cable Pulling Analysis > Perform Cable Pulling Analysis |

The Cable Pulling Analysis tool ships with Designer and allows you to perform "what-if" scenarios for pulling conductors of various sizes through conduit. Calculations resulting from the Cable Pulling Analysis are “what-if” scenarios, and therefore you do not need to have a map open or features selected. The results of the analysis do not affect the data in your map.

Getting Familiar with the Cable Pulling Analysis Interface

The Cable Pulling Analysis interface is divided into the following four main frames:

Performing a Cable Pulling Analysis

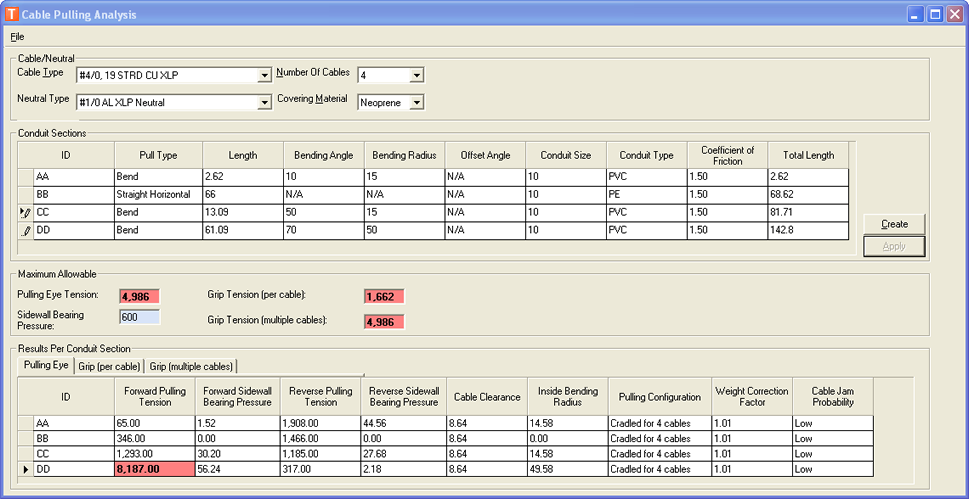

The following example depicts how the Cable Pulling Analysis calculations alert you to problems concerning one or more values you've entered in the Conduit Sections frame. From the fields highlighted in red, we know that Pulling Eye Tension, Grip Tension (per cable), and Grip Tension (multiple cables) calculations exceed the maximum allowable values. To determine which conduit section(s) and which value(s) are causing the alerts, we refer to the correlating tabs on the Results Per Conduit Section frame. From these tabs, we learn that the maximum allowable value for forward pulling tension is violated for all three pull types. We also see that the maximum allowable value for reverse pulling tension is exceeded with the Grip (per cable) pull type.

Maximum allowable alerts for Pulling Eye Tension, Grip Tension (per cable), and Grip Tension (multiple cables)

Pulling Eye tab: Maximum allowable alert for forward pulling tension on conduit section DD

Grip (per cable) tab: Maximum allowable alert for forward pulling tension on conduit section DD and reverse pulling

tension on conduit section AA.

Grip (multiple cables) tab: Maxium allowable alert for forward pulling tension on conduit section DD.

Table 1: Conduit Section Parameters

Column

Description

Input

Error

Action

ID

A value that uniquely identifies each section of conduit

Value is entered by the user

Apply button not enabled

Enter a unique value in the ID column.

Pull Type

A pull type such as bend, straight downward, straight upward, or straight horizontal.

Value is selected from a list of options

Message: Invalid Transition

Change the pull type to a valid configuration. An example of an invalid configuration is Straight Horizontal to Straight Upward.

Length

The length of the conduit section expressed in feet

Value is entered by user for Pull Types other than bend. If Pull Type is bend, the length is automatically derived from the Bending Angle and Bending Radius values. The field may not have a value greater than 99,999.

Bending Angle

The angle of bend expressed in degrees

Value is entered by the user when Pull Type is bend. If Pull Type is other than bend, the value is automatically entered as N/A. The field may not have a value greater than 360.

Bending Radius

The bending radius expressed in feet

Value is entered by the user when Pull Type is bend. If Pull Type is other than bend, the value is automatically entered as N/A.

Offset Angle

The angle offset expressed in degrees

Value is entered by the user for Pull Types other than bend. If Pull Type is bend, the value is automatically entered as N/A

Conduit Size

The diameter of the conduit in inches

Value is entered by the user.

Message: Conduit size violates the minimum standard for this cable. Do you want to continue?

You have entered a conduit size that is less than the minimum standard. Select Yes if you want to continue. Select No if you want to enter a different conduit size.

Conduit Type

A list of conduit types such as fiberglass, PE, PVC, and steel

Value is selected from a list of options

Coefficient of Friction

The coefficient of dynamic friction between the cable and conduit. This parameter takes into account the uneven weight distribution and relative position of multiple cables in the conduit.

Value is entered by the user

Table 2: Results Per Conduit Section (for pulling eye and basketweave grip types)

Column

Description

Associated Editable Parameters

ID

The conduit section ID

ID

Forward Pulling Tension

The amount of tension on a cable being pulled forward through a section of conduit

Cable Type, Number of Cables, Covering Material, Pull Type, Length, Offset Angle, Conduit Size, Conduit Type, Coefficient of Friction

Forward Sidewall Bearing Pressure

The radial pressure experienced by the cable as it is pulled forward through a curved section. Sidewall Bearing Pressure (SWBP) is calculated using the inside radius of the conduit, the inside bending radius, and the tension exiting the bend. SWBP should not exceed 500 lb/ft for uncovered cable and 600 lb/ft for jacketed cable.

Cable Type, Number of Cables, Covering Material, Pull Type, Bending Angle

Reverse Pulling Tension

The amount of tension on a cable being pulled backward through a section of conduit

Cable Type, Number of Cables, Covering Material, Pull Type, Length, Offset Angle, Conduit Size, Conduit Type, Coefficient of Friction

Reverse Sidewall Bearing Pressure

The radial pressure experienced by the cable as it is pulled backward through a curved section.Sidewall Bearing Pressure (SWBP) is calculated using the inside radius of the conduit, the inside bending radius, and the tension exiting the bend. SWBP should not exceed 500 lb/ft for uncovered cable and 600 lb/ft for jacketed cable.

Cable Type, Number of Cables, Covering Material, Pull Type, Bending Angle

Cable Clearance

Clearance between the conduit wall and cable

Cable Type, Number of Cables, Conduit Size

Inside Bending Radius

Inside bending radius of the conduit expressed in feet

Bend Pull Type, Bending Radius, Conduit Size

Pulling Configuration

The relative position of the cables in the conduit (triangular, cradled, and diamond)

Cable Type, Neutral Type, Number of Cables

Weight Correction Factor

Adjustment to the sidewall bearing pressure caused by uneven weight distribution of a single cable in a multiple cable pull

Cable Type, Number of Cables

Cable Jam Probability

Probability of cable jamming based on a ratio and expressed as low, medium, and high

Cable Type, Conduit Size